- Home /

- Dental Design Software

Products

- ARTICULATING SYSTEMS

- BLEACHING PRODUCTS

-

BURS

- BLUWHITE DIAMOND BURS

- BUR ACCESSORIES

- EDENTA STEEL BURS

- IMPLANT DRILL & BUR KITS

- IMPLANT DRILLS & BURS

- INTENSIV CROWN CUTTING BURS

- INTENSIV DIAMOND BURS

- JET CARBIDE BURS

- LABORATORY BURS

- NORTH BEL CARBIDE BURS

- NORTH BEL DIAMOND BURS

- NSK PICO BURS

- ORAL SURGERY BURS

- ORTHO STRIPS

- PERFECTION PLUS STEEL BURS

- THOMAS STEEL BURS

- WAVE CARBIDE BURS

- COTTON PRODUCTS

- DENTURE PRODUCTS

- DIGITAL DENTISTRY

- ENDODONTIC PRODUCTS

- EQUIPMENT

- FINISHING & POLISHING PRODUCTS

- HANDPIECES

- IMPLANT SPECIALIST

- IMPRESSION MATERIALS

-

INFECTION CONTROL

- AUTOCLAVE POUCHES & REELS

- BIBS & BIB HOLDERS

- CLEANING & DISINFECTION

- COMPLIANCE

- DISPOSABLE TRIPLEX SYRINGES

- DRAPES, COVERS & GOWNS

- EYE & FACE SHIELDS

- GLOVES

- HAND CARE

- HANDLING & MAINTENANCE

- IMPRESSION DISINFECTANTS

- MASKS

- PROTECTIVE SLEEVES & COVERS

- SOAKING TANKS

- SUCTION SYSTEM CLEANERS

- SURFACE CLEANING& DISINFECTION

-

INSTRUMENTS

- DIAGNOSTIC INSTRUMENTS

- ENDO HAND INSTRUMENTS

- EXTRACTION FORCEPS

- HANDLING & MAINTENANCE

- LABORATORY INSTRUMENTS

- MIRRORS

- ORTHODONTIC INSTRUMENTS

- PERIODONTIC INSTRUMENTS

- RESTORATIVE INSTRUMENTS

- SCISSORS

-

SURGICAL INSTRUMENTS

- ANAESTHETIC SYRINGES

- ARTERY & TISSUE FORCEPS

- BONE PRODUCTS & FILES

- ELECTROCAUTERY

- ELEVATORS

- LUXATING INSTRUMENTS

- MEASURING INSTRUMENT

- MOUTH PROP

- NEEDLE HOLDER

- OSTEOTOMES & SINUS LIFT

- PERIOTOMES & PERIOSTEAL

- RETRACTORS

- ROOT TIP PICK

- SCALPEL BLADES & KNIVES

- SCISSORS

- SURGICAL CURETTE

- TISSUE FORCEPS

- TISSUE PUNCH

- LABORATORY PRODUCTS

- MOUTHGUARD MATERIAL

- OCCLUSION PRODUCTS

- OFFICE PRODUCTS

- ORAL CARE PRODUCTS

- ORTHODONTIC PRODUCTS

- RESTORATIVE PRODUCTS

- SUCTION PRODUCTS

-

SURGICAL PRODUCTS

- ABSORBENT PRODUCTS

- DEMONSTRATION MODEL

- DRAPES, COVERS & GOWNS

- HANDLING & MAINTENANCE

-

IMPLANT PRODUCTS

- ABUTMENT HOLDERS

- BENEX EXTRACTION KIT

- BONE MILLS & MALLETS

- BONE SPREADING

- GRAFT & MEMBRANE INSTRUMENTS

- GRATFING & MEMBRANE MATERIAL

- IMPLANT CEMENTS

- IMPLANT DRILL & BUR KITS

- IMPLANT DRILLS & BURS

- IMPLANT DRIVER TIPS

- IMPLANT MAINTENANCE

- IMPLANT RESCUE

- IMPLANT TORQUE WRENCH

- MEASURING INSTRUMENT

- OSSEOINTEGRATION DEVICE

- OSSEOUS COAGULUM TRAP

- OSTEOTOMES & SINUS LIFT

- RETRACTORS

- SCREWS, MESH & TACKS

- IRRIGATION & AIRWAY TUBING

- METAL DISHES

- ORAL SURGERY BURS

- SURGICAL ASPIRATORS

- SURGICAL INSTRUMENTS

- SURGICAL UNITS & HANDPIECES

- SUTURES & WOUND CLOSING

- TEETH

- THERMOFORMING PRODUCTS

- WAX PRODUCTS

- XRAY PRODUCTS

DESIGN

Dental Design Software

Amann Girrbach has a wide range of digital software available. The full range can be viewed on the Amann Girrbach website by clicking here, but we have highlighted some of the most popular options below.

The Intelligent Design Software – Developed according to Dental Technology Logic

| The Ceramill Mind design software was developed by Amann Girrbach in close collaboration with dental technicians and meets all requirements. Perfectly coordinated to the Ceramill Map scanner, Ceramill Mind has been seamlessly integrated in the system architecture of the Ceramill system and is characterised by easy handling, process reliability and precision. The user guidance of the CAD programme is orientated to the standard laboratory workflow and greatly simplifies the framework fabrication process. It covers an extensive range of indications from crown and bridge to complex implant restorations or full-denture prosthetics. Features and areas of application are progressively refined allowing the Ceramill Mind to be upgraded by a large number of software modules. |  |

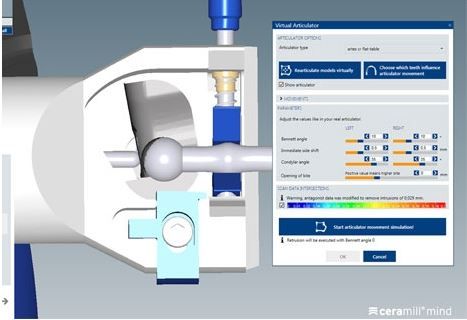

Virtual Artex CR – the Functional Interface between Manual and Digital Prosthetic Dentistry

|

With manual production of dental prosthesis working with the articulator is standard for dental laboratories. In order to achieve the same quality of the works virtually it is only logical and consistent to enable this by means of a CAD-CAM system. The virtual articulator "Ceramill Artex" serves as a bridge between manual and digital techniques: The model pair in the Artex articulator is transfered to the Map 400+ scanner while holding the same Artex mode by means of the Ceramill Transferkit; it is subsequently scanned-in in the appropriate proportion. The movement options of the Artex® CR are thus synchronised digitally and manually. Interfering structures may already be removed thus reducing time-consuming grinding in the patient's mouth to a minimum. |

|

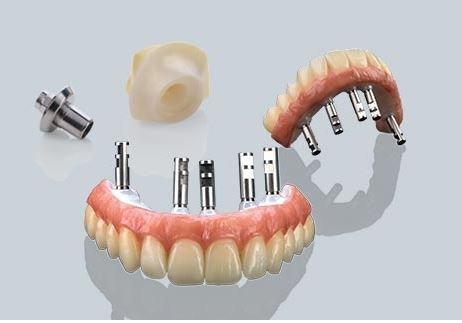

Ceramill Mind Abutment Module for the Fabrication of Customised Abutments and Screw-Retained Bridges

|

Ceramill M-Plant is an upgrade module for the Ceramill Mind design software. The upgrade has the function to design customised titanium and hybrid abutments as well as customised, screw-retained bridges on conical titanium bases made from zirconium oxide, CoCr sinter metal, PMMA (stained), wax, titanium, and CoCr (milled). Corresponding libraries of all common implant systems are available for Ceramill M-Plant which are continuously being expanded.

|

|

Therapeutic Splints – Functional and Accurately Fitting

|

The Ceramill M-Splint was specially developed for the fabrication of customised therapeutic splints. These can be fabricated accurately fitting with interference-free functionality with the aid of the Ceramill Artex articulator. Once the design is complete, the splints can be fabricated from Ceramill Splintec PMMA blanks using Ceramill 5X milling machines. As a Class 2a medical device Ceramill Splintec is suitable for long-term use. |

|

In-house Fabrication of Customised Bars made from Ceramill Sintron (CrCo) or Wax

| Ceramill M-Bars enable fabrication of customised bars made from Ceramill Sintron or Ceramill Wax. Very different bar designs, placement of attachments and retention as well as punching out of holes can also be implemented. The bar can then be fabricated inhouse using 5-axis milling machines. |  |

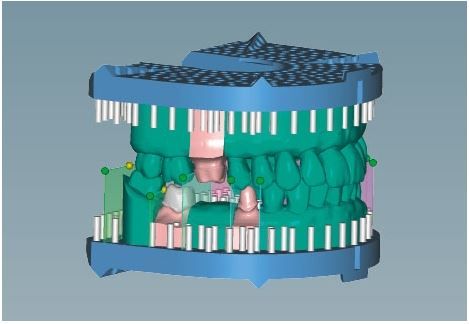

Digital Model Fabrication

| Ceramill M-Build is a software module for digital model fabrication based on intraoral scan data. The Ceramill Mind upgrade is always used to full effect if indications require manual working stages or controls using a model. Without loss of precision and using the method familiar from the manual working technique, Ceramill M-Build ensures the fabrication of interference-free sectioned models using CAD/ CAM and integrates seamlessly into the existing process chain of Ceramill system components. Implementation of the milled models is performed with Ceramill M-Plast - a special modeling resin for Ceramill CAD/ CAM. Implementation of the printed models is performed with the 3D Print Material NextDent Model 2.0. |  |

You can view the full range of Amannn Girrbach software on the AG website by CLICKING HERE